In terms of component maintenance, metal 3D printing can assist:

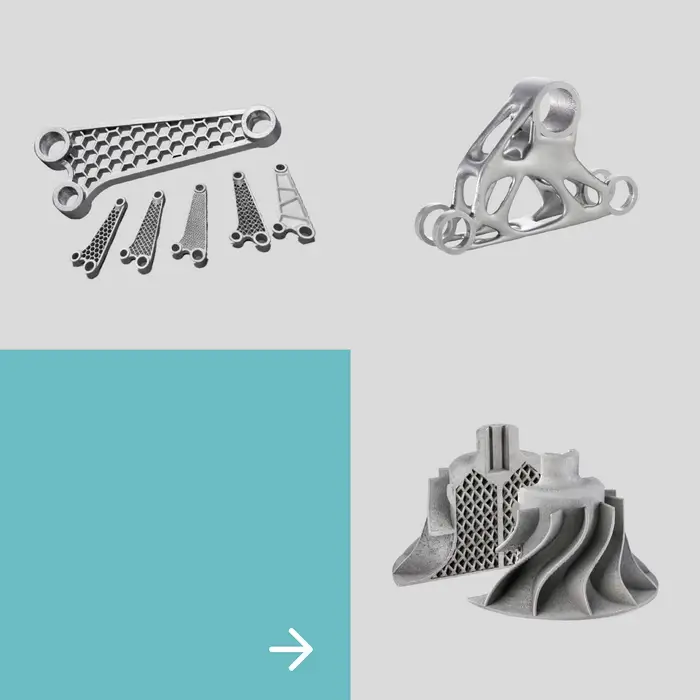

Utilizing metal additive manufacturing (AM, 3D printing) services has revolutionized the field of ship component maintenance. Our cutting-edge technology brings unparalleled benefits:

1Advanced 3D scanning (reverse engineering) technology enables accurate model reconstruction, ensuring seamless integration of repaired or replaced parts.

2With a variety of metal materials available, the produced parts are not only durable but also surpass industry standards.

3Shortened production cycles reduce ship maintenance time, minimizing vessel downtime and enhancing operational efficiency to the fullest extent.

4Reducing material waste aligns with global ESG policies.

Commonly used materials: Titanium alloy, aluminum alloy, stainless steel, nickel alloy

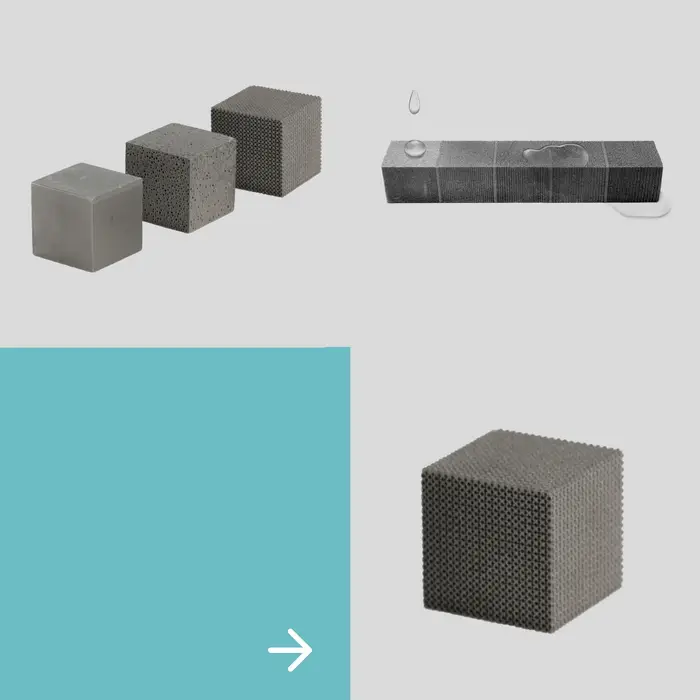

Density: 99.995%

Product accuracy: ±0.05-0.1mm

Product thickness: ±0.2-0.4mm

Production size: 30 cubic centimeters

- Rayvatek's technical team can also assist in product design and provide drawing suggestions.