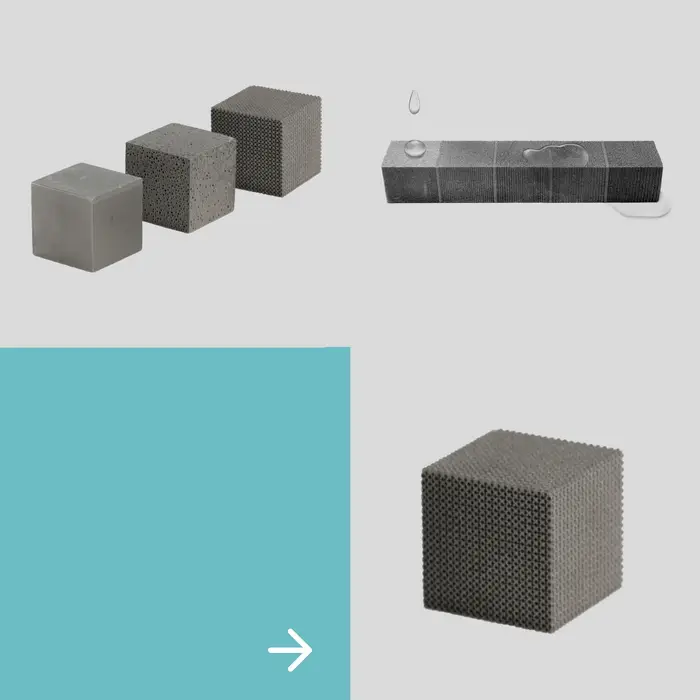

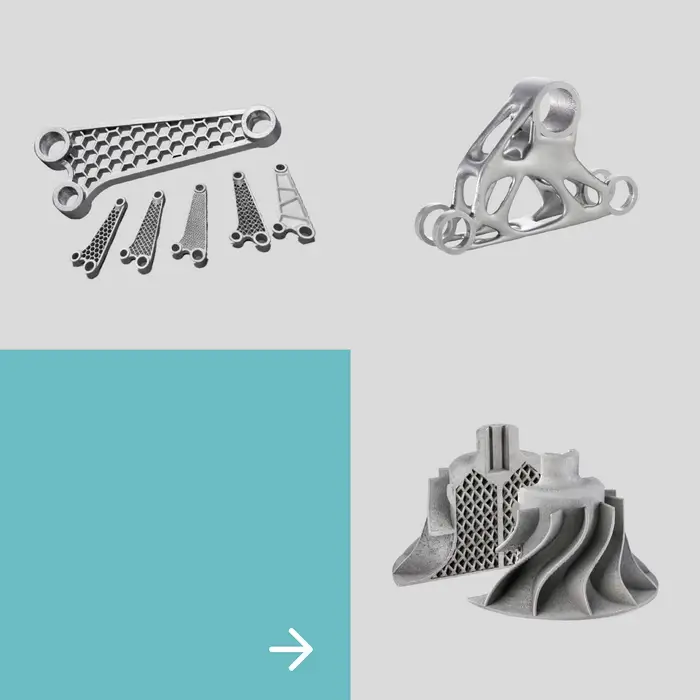

The unique advantages of metal 3D printing's additive manufacturing process:

1Create complex structures in one piece, simplifying product components and reducing weight.

2Shortened development time and cost, enhancing proposal effectiveness.

3Elimination of traditional manufacturing molding costs, enabling small-batch customization production.

4Reduction of material waste, aligning with global ESG policies.

Commonly used materials: Titanium alloy, aluminum alloy, stainless steel, nickel alloy

Density: 99.995%

Product accuracy: ±0.05-0.1mm

Product thickness: ±0.2-0.4mm

Production size: 30 cubic centimeters

- Rayvatek's technical team can also assist in product design and provide drawing suggestions.