Print Beyond Limits

Metal 3D Printing - Engineering Services

Rayvatek’s metal 3D printing manufacturing solutions (PBF Powder Base Fusion / SLM Selective Laser Melting technology) encompass various industries and applications, including aerospace, transportation, heavy machinery parts, plastic injection mold cooling waterway design, industrial heat transfer modules, and consumer electronicsmechanical parts, among others. Of course, 3D scanning (reverse engineering) and metal material analysis services are also part of our offerings.

With our expertise and services, we can help you achieve the following goals:

01.

Complex Structure Design

02.

Simplification of Component Assembly

03.

Rapid Mass Customization

04.

Optimization of Design and Manufacturing Processes

Metal 3D Printing - Applications

Case Study

Clear Filters

Multi-surface Area Structure

Multi-surface Area Structure

Impeller

Impeller

Flow Distributor

Flow Distributor

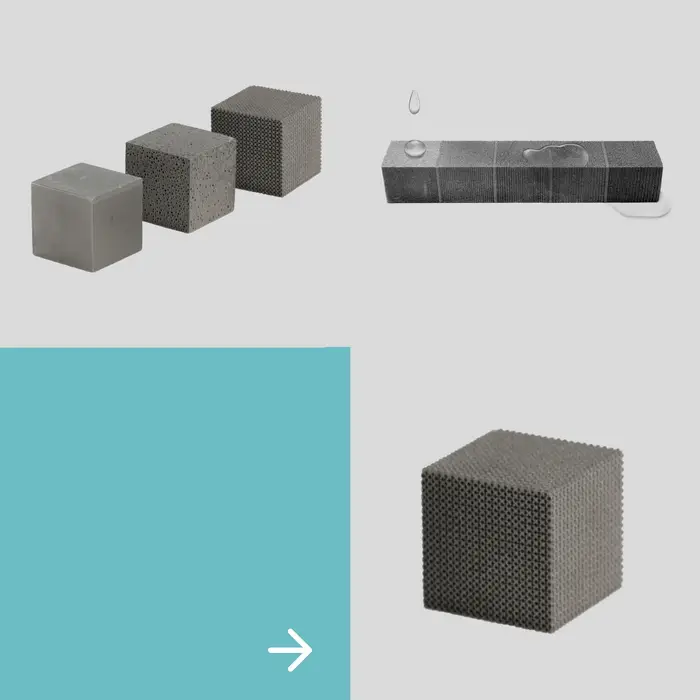

POROUS STRUCTURE

POROUS STRUCTURE

Aircraft Propulsion Parts

Aircraft Propulsion Parts

Aircraft Injection Parts

Aircraft Injection Parts

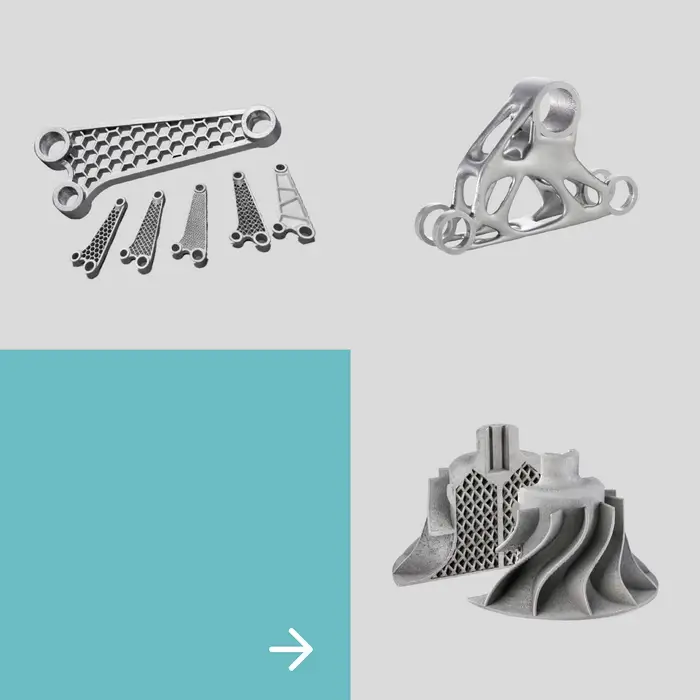

Lightweight Support Frame

Lightweight Support Frame

Topology Optimized Support Frame

Topology Optimized Support Frame

Choose smart and Innovate

Compared to traditional manufacturing processes, Rayvatek has the following advantages:

- Shortening of product development cycle

- Rayvatek Additive Manufacturing

- Traditional Manufacturing

- 4x faster

Compared to traditional manufacturing processes, Rayvatek has the following advantages:

Shorten product development cycle

Rayvatek Additive Manufacturing

Traditional manufacture

4X Faster

Reduction in volume and weight

Rayvatek Additive Manufacturing

Traditional manufacture

- 50 %

volume and weight

Reduction of multiple parts

Rayvatek Additive Manufacturing

Traditional manufacture

- 99 %

multiple parts